Table of Contents

Maintenance

Startup of integrated tubular linear motor

The integrated drive motor are ready to start on the machine without the need to configure. Please refeer to NiLAB Starter Software (Link: NiLAB Starter ) for start-up the motor.

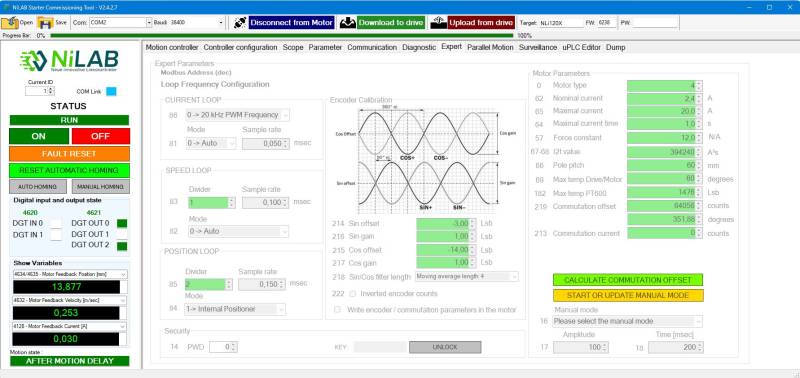

Motor parameter / Servo driver parameterization: The integrated linear motor is provided with parameter data: nominal current, peak current, pole pitch, force constant, etc.. stored inside the integrated drive flash memory. If the end user would like to change these parameters (for example the peak current) must contact NiLAB to have the instruction and the pass code.

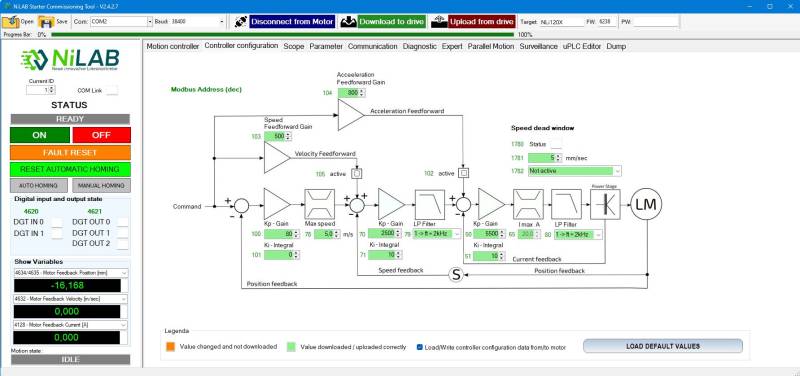

Servo drive optimization: the optimization procedure inside the controller/driver (control loop tuning) is possible using the controller configuration window inside NiLAB Starter Windows Software (Link: NiLAB Starter ).

Encoder polarity and calibration: the integrated encoder (SIN/COS 1Vpp) is calibrated and tested in production. The SIN/COS encoder signal can be visualized using the Scope window inside the NiLAB Starter Sofwtare.

Commutation adjustment: this value is calculated and stored inside the integrated drive memory during the production and test procedure.

General preconditions

Before starting up the drive please follow this check list, Respect all safety instruction and notes below:

- Check all electrical connections and all mechanical components and their safety operation

- Check availability of all supply involved with servo driver/controller

- Check the safety warranty of people involved with machine operation

- Check the proper installation of the motor

- Check the correct power connection between the motor and the drive

- Check the function of limit switch, over-travel switch where available

- Check function of emergency brake or stop

- Check machine mechanics arrangement (mechanical installation)

| Danger to life, heavy injury or damage by failure or malfunction on mechanical or electrical components! Risk of injury or danger to life, as well as damage due to nonconformity of warning and safety notes! |

General start-up procedure

For general startup procedure of integrated drive motors please refer to NiLAB Starter Software section.

Maintenance and check of motor components

Integrated drive linear motors are maintenance free components but due to external influences the motor can be damaged during operation. This result in preventive maintenance of the motors with service intervals on machine side checking all parts involved:

- Check the state of stator and the slider

- Check screws and connections

- Check the state of power and signal cables

- Check the state of linear guides (mechanical components) evaluation wear and state of lubrication when use

Suggested maintenance schedule for applications

| PHASE | LESS THAN 150 MOV/MIN | FROM 150 TO 300 MOV/MIN | MORE THAN 300 MOV/MIN |

| Startup | Check | Check | Check |

| After 3 months | Check | Check | |

| After 6 months | Check | Check | Check |

Maintenance activities

Check

Please consider the following checklist:

1) Is the motor shaft clean?

2) May the motor shaft slide freely?

If the above conditions are not met, please proceed with the cleaning.

Cleaning

It is recommended not to use solvents, kerosene or similar products and to consider the following checklist:

1) Remove the shaft from the motor body dismounting the stop ring at the ends.

2) Clean the shaft with alcohol and a soft cloth.

3) Clean the internal parts of the motor body with compressed air to remove contaminants.

Instructions for lubrication

The polymer sliding bearings are lubrication free bearing. So, there is no need of use of lubricants.