meta data for this page

Siemens Sinamics S120 / G120

Blocksize

Please considerr that the standard winding of the motor are compatible with 230VAC or 400VAC servo drives.

Select a model of the blocksize (power module of the drive) considering the motor datasheet values: https://www.ni-lab.online/new_websmart/read_datasheet.php

Rated current of the motor must be fullfilled from the rated current of the drive.

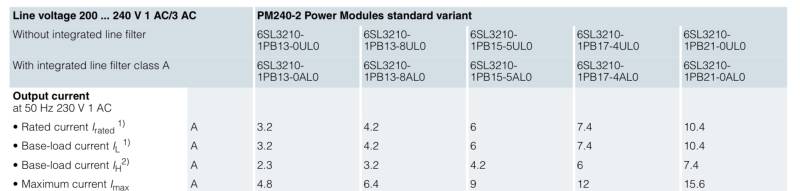

G120 (230 VAC power lines)

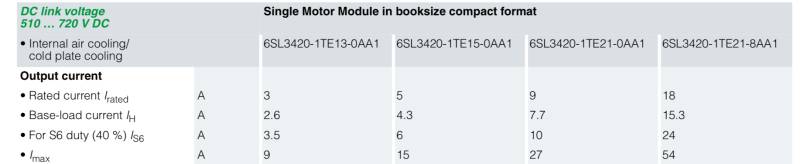

S120 (400 VAC power line)

Limitation

| The pole position identification with S120 and third party motor is not possible. So, this identification function must be deactivated and the commutation angle must be manually entered. (Parameter p1982=0) |

Motor feedback connection

The motor feedback must be connected using driveCliq converter SMC20 or SME20.

| SMC20 6SL3055-0AA00-5BA3 | SME20 6SL3055-0AA00-5EA0 |

|  |

Converter pinout

| NiLAB cable wire colors | Signal | SMC20 d-sub25 female | SME20 M23 pinout |

| Yellow | SIN+ | 3 | 5 |

| Green | SIN- | 4 | 6 |

| Gray | COS+ | 6 | 1 |

| Orange or pink | COS- | 7 | 8 |

| Blue | PTC+ | 25 | 9 |

| Violet | PTC- | 13 | 7 |

| Red | +5VDC | 1+14 | 2+12 |

| Black | GND | 2+16 | 10+11 |

| White-Black | – | – | – |

| Brown | – | – | – |

| White | – | – | – |

| Brown-White | – | – | – |

| Shield | – | 5+8+24 | – |

Parametrization

When creating the drive from scratch, the correct sequence to follow is:

1) Fill the data as in the table below (two example motor are listed in the table)

| Parameter | Description | GDI250QS | GD350ES |

| P305 | Nominal current | 1.2 A | 3.7 A |

| P311 | Nominal speed | 100 m/min | 100 m/min |

| P315 | Pole pitch | 60 mm | 60mm |

| P316 | Force constant | 52 N/A | 72 N/A |

| P322 | Max speed | 100 m/min | 100 m/min |

| P323 | Max current | 4.8 A | 16 A |

| P338 | Current limit | 4.8 A | 16 A |

| P341 | Slider weight | 1.5 kg | 3 Kg |

| P350 | phase resistance | 21.5 ohm | 5.03 ohm |

| P356 | phase inductance | 35 mH | 5.68 mH |

| P431 | commutation angle | to calculate | to calculate |

*) Note that the P341 must be calculate with Pole position identification procedure.

**) As regards the parameter P431, ask NiLAB for the correct value of the motor if is not listed in the table.

2) The equivalent circuit data p350 and p356 will then need to be re-entered after the download. This happens because after the system calculations, these values are overwritten. The calculations must be performed to provide consistent values for the current and speed controllers.

3) After the download, enter the datasheet values for resistance and inductance, and also insert a filter on the encoder p1441=1ms or 2ms. Then, deactivate the commutation angle measurement and/or verification by setting p1982=0.

4) For correct operation, the U and V phases must be swapped.

5) If the data already exists, only P431 and P1982=0 need to be modified, remembering that p431 can only be modified by setting p10=4 and then setting it back to p10=0.

Pole position identification

The drive must be enabled using the inductance-based pole position identification (p1980 = 10 ⇒ Motion-based).

Please set the parameter p0325 ⇒ Motor pole position identification current 1st phase ⇒ Rated Current of the motor and parameter p0329 ⇒ Motor pole position identification current ⇒ Rated current of the motor. See attached Siemens manual section for reference::green_drive_motors:pole_position_identification.pdf

Detailed procedure

1. Enable the measure of the commutation angle setting P10=4, P1982=1, P1990=1, P1980=10, P1993=50% of the rated current of the motor. P1994=2 sec, p1997=max value.

2. After the movement p431 is shown.

3. Change the parameter p10=0, P1982=0 and P1980=0 that means pole position detection measure disabled.