meta data for this page

Pacdrive 3 - Schneider Electric

MACHINE EXPERT CONFIGURATION

Example of configuration for L050P1215-GH linear motor.

Please, if the motor is different consider the right data using datasheet engine: https://www.ni-lab.online/new_websmart/read_datasheet.php

Inside the Drive section, set MotorIdentification to motor without type plate/2 and MotorTemperatureMonitoring set to Sensor / 2 (a jumper on the temperature connectors on the power port must be arranged).

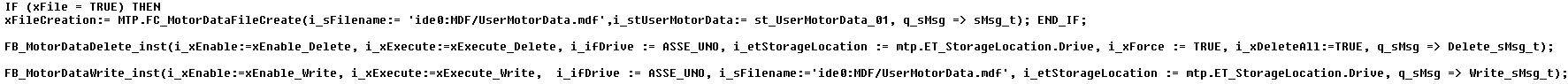

The Motor Data must be stored in the Drive Memory, with these instruction (ASSE_UNO is the name of Lexium LXM62 Linear Drive)

In order to store the motor data, switch Sercos phase to 2. Create the mdf file set to TRUE the xFile variable, then Delete the data inside the drive setiing xEnable_Delete and xExecute_Delete to TRUE. Finally, write the motor data inside the drive setting xExecute_write and xEnable_Write to TRUE. After the sucessfully procedure, swtich the power supply of the encoder and the drive off. When the drive is restarted, set SERCOS phase to 4. The servo drive must be without error showing the encoder position value without errors.

Now select the PSM_Lexium62 power supply window, provide the power lines (400V) to the drive and set PowerSupplyCheckSet to 1. Go back to the drive section and calculate the commutation angle setting MotorCommutationMode to with movement / 0 and set the MotorCommutationControl to detect and write / 1.

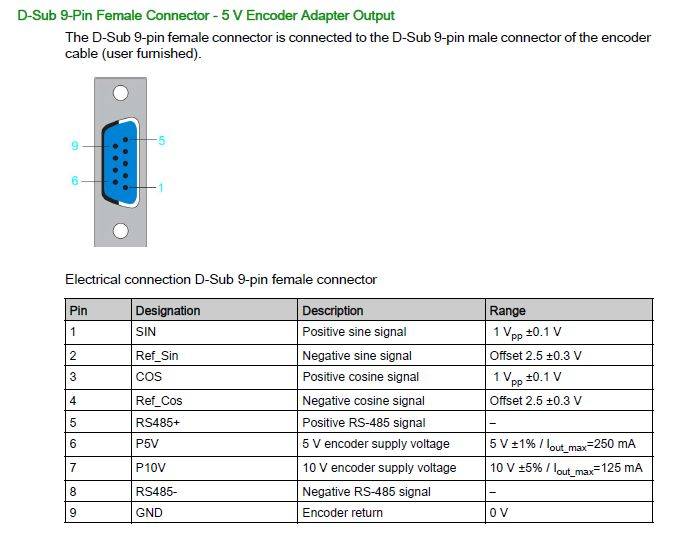

CONNECTOR PINOUT

WARNING: DO NOT REMOVE THE 24VDC FROM DRIVE WITHOUT REMOVE THE 24VDC ON THE ENCODER POWER LINES.

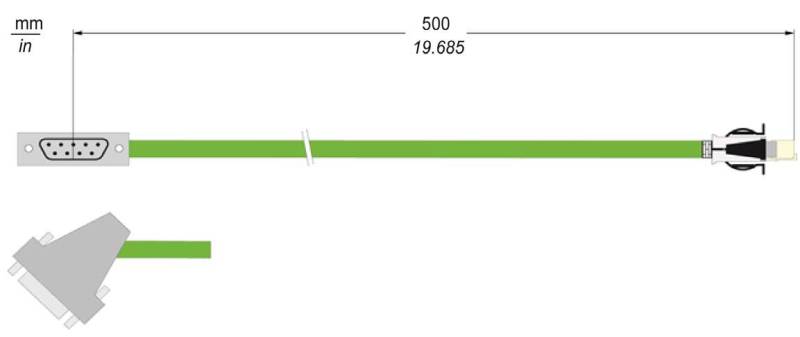

In order to use with LXM62D servo drive, please use the adapter cable VW3E2092R005 (Feedback adapter SH3/MH3 servo motor L=0,5m) in combination with our DE20600780-5M (5 meter Revenc encoder cable for LXM62 Servo drive) with DSUB9 pin male.

| Signal | DE20600780 D-SUB 9 Pin | VW3E2092R005 D-SUB 9 Pin | Feedback connector on the LXM62D servo (RJ45 + power lines) |

| SIN- | 6 | 1 | 6 |

| SIN+ | 3 | 2 | 3 |

| COS- | 2 | 3 | 2 |

| COS+ | 1 | 4 | 1 |

| DATA- | 5 | 6 | 5 |

| DATA+ | 4 | 7 | 4 |

| GND | 7 | 9 | B |

| NC | - | - | A (Encoder Power is not connected, the encoder is powered externally with 24VDC) |

Note that using Machine Expert, the Feedconstant of the encoder must be set to the used encoder configuration.

For example, with a output sine period of 2mm, the feedconstant in Mechanic must be set to 1000.